In the second Helsinki data science meetup of 2018, data enthusiasts took a trip to Hyvinkää to learn how our host, Konecranes, uses data science and analytics to optimize performance across sales, maintenance, safety and service quality.

Ulla Kruhse-Lehtonen, CEO and co-founder of DAIN Studios, opened the event with Juha Pankakoski, Executive Vice President at Konecranes, followed by four compelling and thought-provoking presentations by Konecranes’ in-house experts. Here is a summary of what we learnt…

Juha Pankakoski, Executive Vice-President at Konecranes, gave us an introduction to Konecranes, highlighting its track record of industry-shaping innovations over the last 100 years. With connected cranes and equipment growing exponentially, Konecranes has the most immense data repository in the lifting industry. The Helsinki data science community were enthralled with Konecranes’ iPAD application that gives the experience of augmented reality by maneuvering a virtual crane attached to the ceiling. The key takeaway message from the presentation was that data-driven technologies are redesigning industrial systems.

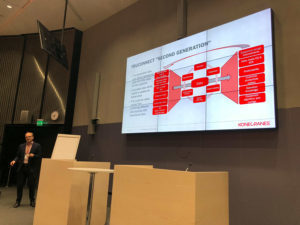

Timo Harjunen, Director, Digital Platform Development, introduced TruConnect as part of the Konecranes digital journey. TruConnect uses sensors to collect data such as safety-related occurrences, operating statistics – such as running hours, overloads, emergency stops and load spectrums. Such data is used to estimate, for example, the remaining design working period of selected components of equipment and/or cranes to estimate predictive maintenance needs.

Mikael Björkbom, Senior Chief Engineer, continued the focus on predictive maintenance presenting the case of Agilon. The aim was to explore the ability to predict failure in advance to inform the maintenance schedule, boost productivity and enhance safety by using motor data. The presentation spoke the language of the typical data scientist with feature extraction of some 100 features, machine learning, as well as training and testing models. The key challenge for predictive maintenance was that Konecranes did not have enough “failure data” with barely a sample of 20 to build results. On the up-side, it was pretty convincing that predictive modelling and analytics can save time, effort and money. The success is in the features.

Alun Jones, Data Scientist, presented sales forecasting based on maintenance activity. The presentation made that case for transforming data into information and then intelligence. Alun gave some examples of how to leverage data, whether it be internal, external, structured or unstructured. Using the example of Konecranes, Alun presented a case where by taking maintenance analytics, sales can be forecasted, which in the end leads to efficient business processes both within Konecranes, and for their customers.